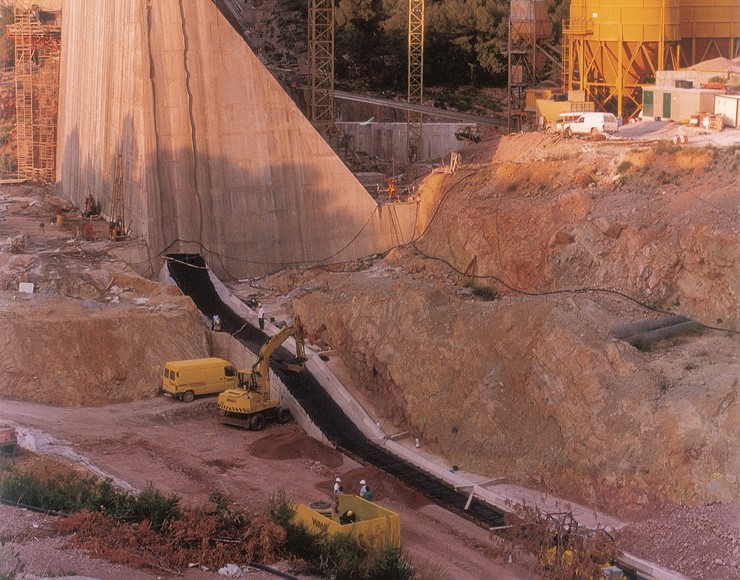

Reservoir Lining

WALO’s Dense Asphaltic Concrete (DAC) lining system provides a strong, flexible, non-toxic lining, which is thin enough to flex under extreme pressure without cracking, while being totally safe for human, animal and marine life. These factors make it perfect for water storage.